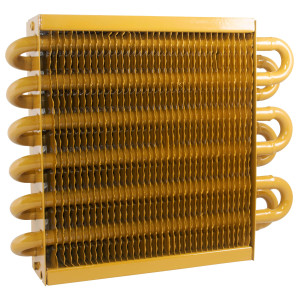

Gulfcoat IEA-OC-006 Marineclear Anti Corrosion spray Protection Coating Aerosol 12oz corrosion preventative inhibitor formulated to improve adhesion, moisture resistance, UV protection Modine

Use: Developed in response to customer demand for a protective coating to be applied on small jobs and or in remote areas. Original Designed for HVAC Coil, can be applied to any surfaceCorrosion Resistance: Products have a robust synthetic multi-polymer resin backbone that is suitable for most environments and will maintain its appearance after many years exposure to the elementsUV Degradation: Built in enhanced UV inhibitors form a protective barrier throughout the paint film. As a result, UV degradation of individual polymer molecules are reduced and the film integrity maintainedGloss Retention: A high gloss finish is applied that is smooth, limits dirt and debris buildup, and allows for easy equipment cleaningResistance: Corrosion durability shall be confirmed through testing to no less than 5,000 hours salt spray resistance per DIN 53167 (ASTM B117-11) using aluminum test couponsWeight : 1.08 LBR

Volume : 0.03 FTQ

Model : IEA-OC-006

UPC-EAN : 850021531027

Spray Applied Corrosion Resistant Coating

GulfCoat marine coatings provide a HVAC COIL coating system for added corrosion protection on aluminum and copper finned RTPF and MCHX coils. GulfCoat coatings help to reduce the accelerated corrosion of HVAC coils. By following the coating and maintenance instructions, end users should expect extended life cycles and keep the energy consumption to a nominal level.

Directions

Surface must be free of grease, rust, and wax. Prior to coating, follow these steps:

Clean coils with appropriate cleaner ndash; use GulfCoat Surface Prep

Rinse with clean water

Allow coil to thoroughly dry

Mask off or protect areas from overspray

Allow product can to warm to room temperature

Mask off or protect areas from overspray. Allow the can to warm to room temperature. Shake until mixing ball rattles, then continue to shake for two minutes. Move can with light to medium strokes. Let paint become tacky between coats. After use, invert can and spray to clear valve.

Product Description

GulfCoat MarineBlue, MarineClear, and MarineGold corrosion resistant coatings are specifically designed for the protection of HVAC coils and components. GulfCoat MarineBlue is formulated to improve adhesion, moisture resistance, UV protection, and corrosion resistance. The product can be applied on-site or at your premises after HVAC units have been manufactured and installed.

Specifications

HVAC coil and components shall have GulfCoat MarineBlue, MarineClear, and MarineGold spray applied with no runs or sags. The spray coating process should ensure a uniform dry film thickness of 10-36 mu;m (0.4 -1.4 mils) and meet 5B rating for crosshatch adhesion per ASTM D3359-09. Corrosion durability shall be confirmed through testing to no less than 5,000 hours salt spray resistance per DIN 53167 (ASTM B117-11) using aluminum test coupons.